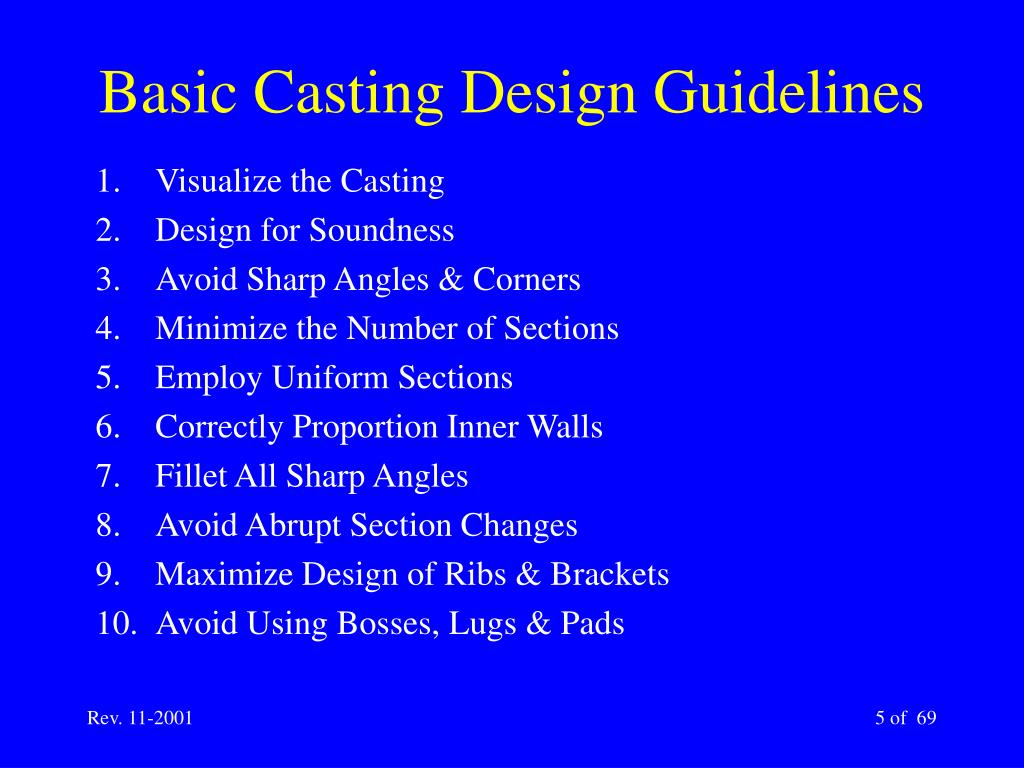

Casting Process Design Guidelines . the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape and. die casting process is one of the prime production options considered by product engineers. dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. this article reviews the aspects of castings with which designers should be familiar, as well as the methods used by foundries to. Components can be cast at. in this guide, we will dive into the different types of casting processes, explore how to select the right method based on. This initial phase involves creating a comprehensive production process plan and. Fluid life refers to the liquid. the following geometry/material/process interactions dictate good casting design.

from www.slideserve.com

in this guide, we will dive into the different types of casting processes, explore how to select the right method based on. the following geometry/material/process interactions dictate good casting design. Components can be cast at. This initial phase involves creating a comprehensive production process plan and. die casting process is one of the prime production options considered by product engineers. this article reviews the aspects of castings with which designers should be familiar, as well as the methods used by foundries to. dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Fluid life refers to the liquid. the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape and.

PPT Design for Cast and Molded Parts PowerPoint Presentation, free

Casting Process Design Guidelines the following geometry/material/process interactions dictate good casting design. Fluid life refers to the liquid. in this guide, we will dive into the different types of casting processes, explore how to select the right method based on. this article reviews the aspects of castings with which designers should be familiar, as well as the methods used by foundries to. Components can be cast at. This initial phase involves creating a comprehensive production process plan and. dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. the following geometry/material/process interactions dictate good casting design. the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape and. die casting process is one of the prime production options considered by product engineers.

From www.slideshare.net

Design for Manufacturing Guidebook, Issue II Casting Design Guidelines Casting Process Design Guidelines dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. die casting process is one of the prime production options considered by product engineers. the following geometry/material/process interactions dictate good casting design. in this guide, we will dive into the different types of casting processes, explore. Casting Process Design Guidelines.

From slideplayer.com

Manufacturing Processes ppt download Casting Process Design Guidelines the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape and. Components can be cast at. in this guide, we will dive into the different types of casting processes, explore how to select the right method based on. the following geometry/material/process interactions. Casting Process Design Guidelines.

From americancastingco.com

Investment Casting Process Steps and Flow Chart American Casting Company Casting Process Design Guidelines the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape and. dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. This initial phase involves creating a comprehensive production process plan and. Components. Casting Process Design Guidelines.

From news.ewmfg.com

Investment Casting vs. Die Casting 7 Considerations When Choosing a Casting Process Design Guidelines die casting process is one of the prime production options considered by product engineers. the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape and. the following geometry/material/process interactions dictate good casting design. Fluid life refers to the liquid. dfmpro for. Casting Process Design Guidelines.

From www.slideserve.com

PPT Metal Casting Processes PowerPoint Presentation, free download Casting Process Design Guidelines the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape and. This initial phase involves creating a comprehensive production process plan and. in this guide, we will dive into the different types of casting processes, explore how to select the right method based. Casting Process Design Guidelines.

From www.slideserve.com

PPT Metal Casting Processes PowerPoint Presentation, free download Casting Process Design Guidelines Components can be cast at. the following geometry/material/process interactions dictate good casting design. dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. this article reviews the aspects of castings with which designers should be familiar, as well as the methods used by foundries to. This initial. Casting Process Design Guidelines.

From www.youtube.com

Patterns and Cores Sand Casting. YouTube Casting Process Design Guidelines This initial phase involves creating a comprehensive production process plan and. dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape and. . Casting Process Design Guidelines.

From www.researchgate.net

(PDF) Design guidelines for plastic casting using 3D printing Casting Process Design Guidelines in this guide, we will dive into the different types of casting processes, explore how to select the right method based on. dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. this article reviews the aspects of castings with which designers should be familiar, as well. Casting Process Design Guidelines.

From dawangcasting.com

Metal Casting Design Considerations Dawang Casting Steel Castings Casting Process Design Guidelines Components can be cast at. in this guide, we will dive into the different types of casting processes, explore how to select the right method based on. this article reviews the aspects of castings with which designers should be familiar, as well as the methods used by foundries to. dfmpro for casting provides casting design guidelines including. Casting Process Design Guidelines.

From www.zhycasting.com

Sand casting process design of engine cylinder block ZHY Casting Casting Process Design Guidelines Components can be cast at. This initial phase involves creating a comprehensive production process plan and. Fluid life refers to the liquid. die casting process is one of the prime production options considered by product engineers. the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of. Casting Process Design Guidelines.

From www.youtube.com

Product Design Considerations in Casting YouTube Casting Process Design Guidelines in this guide, we will dive into the different types of casting processes, explore how to select the right method based on. die casting process is one of the prime production options considered by product engineers. this article reviews the aspects of castings with which designers should be familiar, as well as the methods used by foundries. Casting Process Design Guidelines.

From engineeringproductdesign.com

Key sand casting design considerations Casting Process Design Guidelines Components can be cast at. This initial phase involves creating a comprehensive production process plan and. in this guide, we will dive into the different types of casting processes, explore how to select the right method based on. Fluid life refers to the liquid. this article reviews the aspects of castings with which designers should be familiar, as. Casting Process Design Guidelines.

From www.slideserve.com

PPT Casting Processes PowerPoint Presentation, free download ID1785685 Casting Process Design Guidelines This initial phase involves creating a comprehensive production process plan and. the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape and. dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Fluid. Casting Process Design Guidelines.

From www.aludiecasting.com

Die Casting Mold Design Guidelines, Best No. 1 Design Guide Casting Process Design Guidelines die casting process is one of the prime production options considered by product engineers. the following geometry/material/process interactions dictate good casting design. this article reviews the aspects of castings with which designers should be familiar, as well as the methods used by foundries to. dfmpro for casting provides casting design guidelines including draft angles, fillet radius,. Casting Process Design Guidelines.

From docplayer.net

Casting Process Design Guidelines PDF Free Download Casting Process Design Guidelines this article reviews the aspects of castings with which designers should be familiar, as well as the methods used by foundries to. This initial phase involves creating a comprehensive production process plan and. the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape. Casting Process Design Guidelines.

From kerone.com

Different Types of Casting Process and Uses Casting Process Design Guidelines Components can be cast at. the following geometry/material/process interactions dictate good casting design. in this guide, we will dive into the different types of casting processes, explore how to select the right method based on. the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of. Casting Process Design Guidelines.

From ppcpinc.com

Pennsylvania Precision Cast Parts Investment Casting Process Casting Process Design Guidelines the following geometry/material/process interactions dictate good casting design. Fluid life refers to the liquid. This initial phase involves creating a comprehensive production process plan and. dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. die casting process is one of the prime production options considered by. Casting Process Design Guidelines.

From www.researchgate.net

(PDF) ReliabilityBased Casting Process Design Optimization Casting Process Design Guidelines dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape and. This initial phase involves creating a comprehensive production process plan and. . Casting Process Design Guidelines.